La carne esposta in un banco refrigerato può presentare due macro tipologie di alterazione che danneggiano economicamente gli utenti (in particolare le macellerie):

• l’ossidazione della superficie della merce (variazione cromatica);

• la perdita di massa del 2.96% in 24H e 5.56% in 48H.

La prima problematica si traduce nella necessità da parte dell’operatore di asportare lo strato di carne ossidata (per poter rendere la merce visivamente più appetibile), con un evidente danno economico. La seconda comporta un danno economico dovuto al delta massa della carne esposta nell’arco delle 24H o 48H.

Le tecnologie utilizzate fino al 2015 per la conservazione della carne si dividono storicamente in due tipologie: una con ventilazione forzata e una statica.

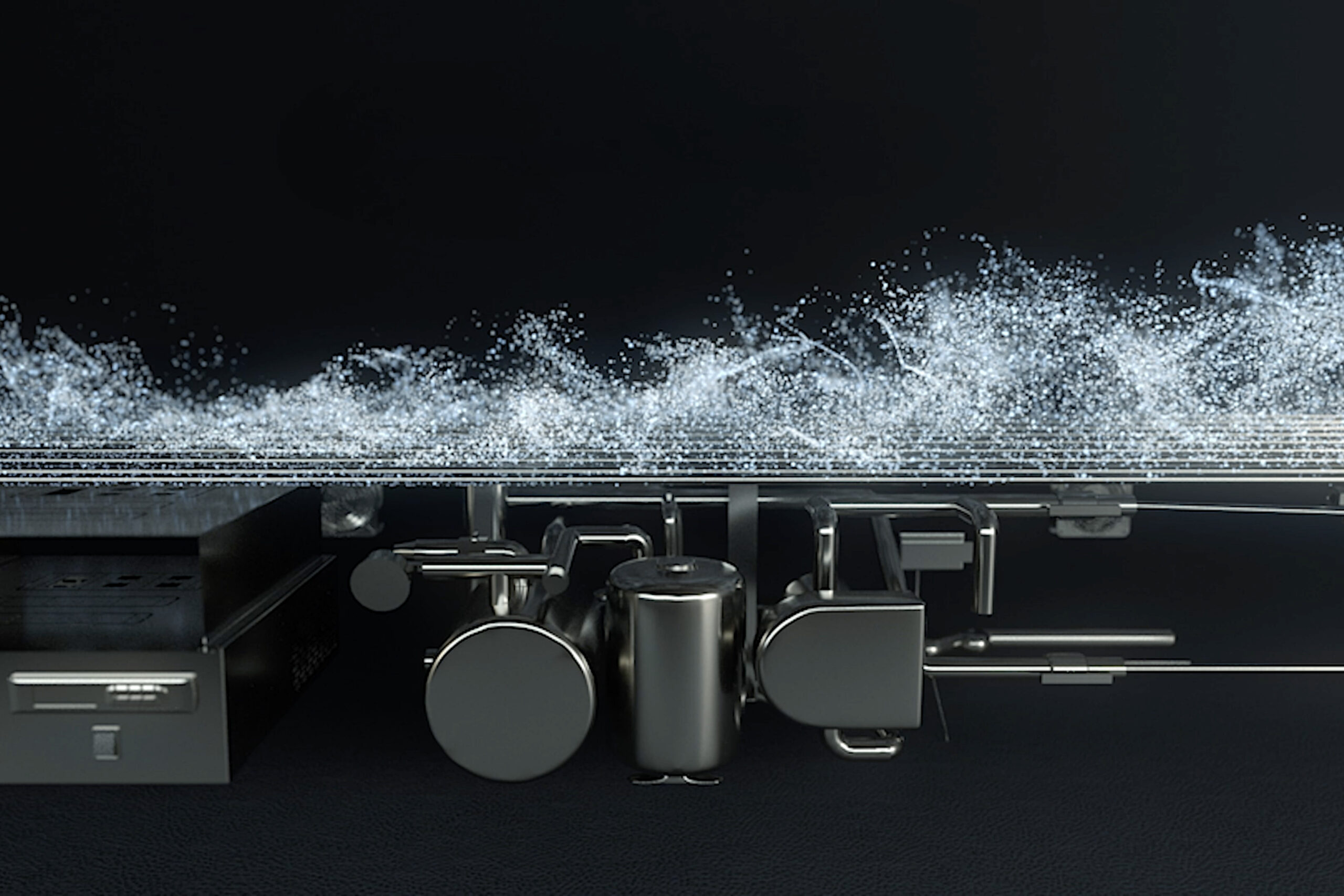

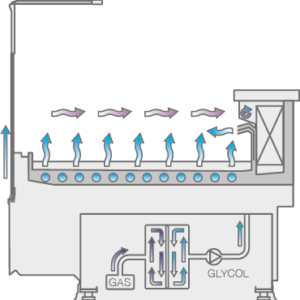

Con G-Concept Criocabin ha puntato invece a un sistema ibrido, semi-statico, con un sistema di ventilazione molto lento e molto poco energivoro. A differenza dai sistemi finora noti, l’intero impianto refrigerante è alimentato con glicole.

L’elevato coefficiente di scambio termico del liquido refrigerante glicole ha permesso di lavorare con una temperatura di refrigerazione più elevata (a parità di performance) permettendo così un notevole risparmio energetico, rispetto a un normale impianto refrigerato a gas.

Il raffreddamento del liquido avviene mediante uno scambiatore acqua/gas posto sotto il banco stesso e di progettazione esclusiva di Criocabin.

L’innovativo G-Concept ha portato al raggiungimento dei due principali obiettivi:

1. il sistema G-Concept non ossida la carne;

2. grazie alla ventilazione particolarmente contenuta e al controllo ottimale di umidità e temperatura, il calo della massa della carne è inferiore del 50% rispetto ad un normale banco ventilato con un importante risparmio economico per la macelleria (1.35% dopo 24H e 2.75% dopo 48H).

Consideriamo che in un banco di lunghezza media di 5 m è possibile esporre circa 170 kg di carne. Da questo dato, si stima una perdita di peso giornaliera di 4,25 kg su un banco ventilato contro circa 1.7 kg del sistema G-Concept.

Le perdite annuali per un banco ventilato sono stimate in:

– 4,6 kg × 250 gg lavorativi = 1.150 kg/anno (nel caso migliore).

Le perdite annuali per sistema G-Concept sono stimate in:

– 2,3 kg × 250 gg lavorativi = 575 kg/anno (nel caso peggiore).

Un macellaio con un negozio di medie/piccole dimensioni impiega in media 2H alla mattina e 2H alla sera per mettere e togliere la carne dal banco per portarla in cella. Con il sistema G-Concept il macellaio non deve più compiere queste operazioni: può lasciare la carne all’interno del banco e riempire solo la merce venduta.

Per la notte (e durante le pause di chiusura) dovrà solo preoccuparsi di chiudere le tende notte.

Si può quindi stimare un risparmio di lavoro di circa 3h/gg:

3 h/gg × 250 gg lavorativi = 750 h/anno